Throughout the world today we are being told to consume less. The mantra for the green movement has been to reduce, recycle, reuse. This environmentally responsible attitude is being accepted by people and businesses as the way of the future. What may surprise people is that even the construction industry is trying to become greener. They are looking to products that will not only save energy in the future, but that will be environmentally friendly during the construction process.

Throughout the world today we are being told to consume less. The mantra for the green movement has been to reduce, recycle, reuse. This environmentally responsible attitude is being accepted by people and businesses as the way of the future. What may surprise people is that even the construction industry is trying to become greener. They are looking to products that will not only save energy in the future, but that will be environmentally friendly during the construction process.

A great example of Bali Garden Landscape Design going green is the increased use of insulated concrete forms (ICFs). This method of construction is one of the most green building methods available to contractors. When developed properly, the foam forms are made from almost all recycled materials. They are shipped to the exact size requested, and they quickly lock into place. In other words, the environment is helped because materials are recycled, less waste is created at the construction site, and less energy and time are used to build a building’s walls.

The walls that are constructed are of course green. By using ICF concrete $15000 Bathroom Remodel a contractor uses less wood. This is because walls are no longer made of wood studs. Instead, walls are concrete sealed in foam. The less wood that is used in home construction means more trees being left in the forest. Most people who are thinking green agree that saving a tree is a good way to help the environment.

Another way to help the environment is to keep material out of landfills. As mentioned earlier, the ICF concrete form can be made of mostly recycled materials. The key to this is the center support structure of the form. This structure should be made of a recycled alloy metal. This keeps the metal out of the landfill and adds a “rebar” strength to the center of the concrete wall. Plus, a well constructed ICF will have an alloy center that folds together. This reduces the amount of fuel used to ship the forms, and saves money.

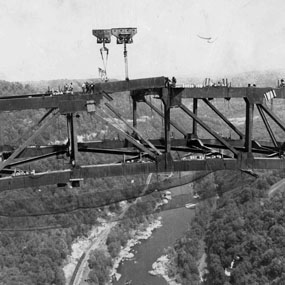

Construction